FHTT series flat-top tower cranes: mainly targeting the thermal power construction market, with a maximum rated lifting moment of 420~3200t.m and a maximum rated lifting capacity of 24t~160t. They adopt a horizontal jib, no tower cap, and trolley luffing, featuring a large working radius and high efficiency.

FHTP series flat-arm tower cranes: mainly targeting civil buildings, hydropower markets, etc., with a maximum rated lifting moment of 100~315t.m, a maximum rated lifting weight of 8t~16t, using a horizontal jib, with a tower top, trolley luffing, and features such as light weight and high work level.

FHTD series luffing jib tower cranes: mainly targeting super high-rise buildings and thermal power construction markets, with a maximum rated lifting moment of 480~3200t.m and a maximum rated lifting capacity of 24t~160t. Features include luffing jib, front-mounted jib pivot structure, small tail space, fast action speed of various mechanisms, and a wide speed regulation range.

FZQ series self-erecting tower cranes: are large lifting machinery equipment suitable for installation operations in large construction projects such as thermal power plants, hydropower plants, nuclear power plants, petroleum, chemical industry, metallurgy, and high-rise steel structures. They are especially suitable for the installation of tower boilers in power plants and the construction of high-rise buildings with limited space on the construction site.

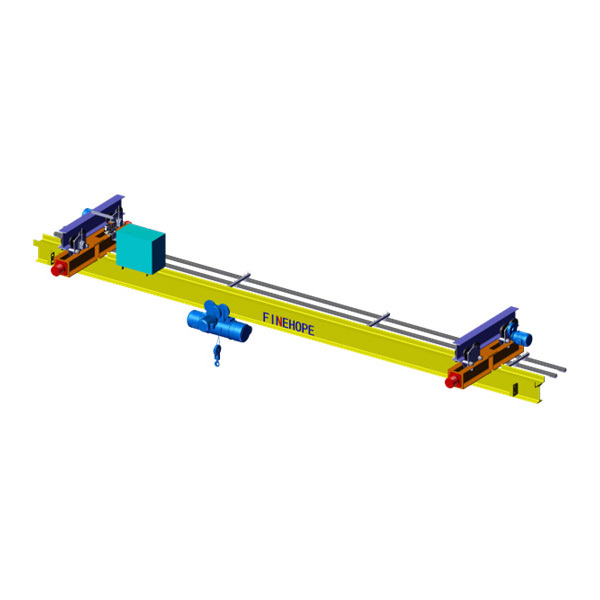

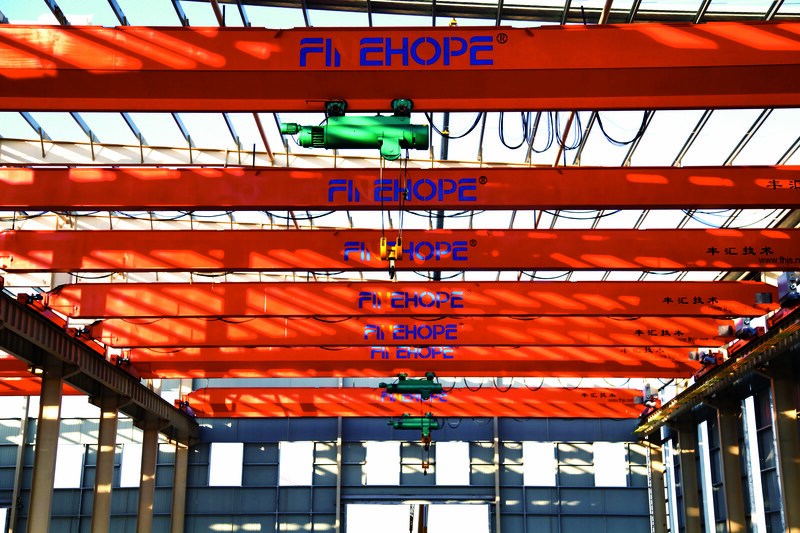

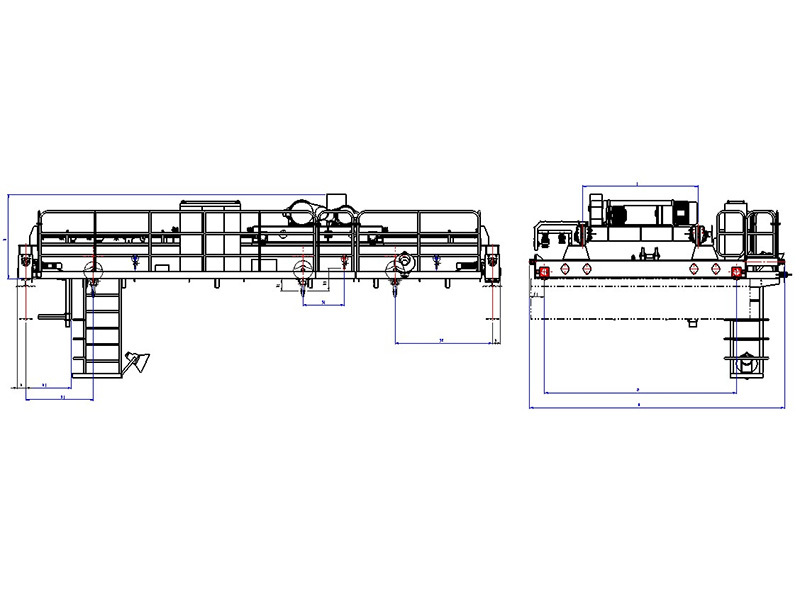

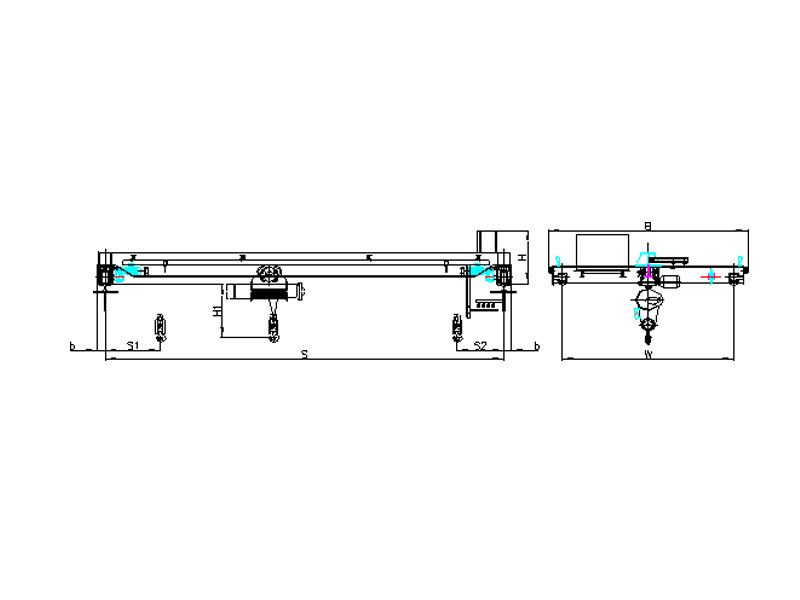

FHLD Electric Single-Beam Bridge Crane

Finehope bridge cranes utilize internationally advanced design concepts. They feature novel structural designs, with bridge frames and end beams offering overlapping and butt-joining combinations. Trolleys are available in European and Chinese styles, and various modular combinations are possible to meet user requirements and suit different environmental needs. Performance and parameters meet international advanced standards. They are widely used in nuclear energy, power generation, ultra-high voltage transformers, and civil applications.

FHMG gantry crane for box girders: Based on a compact European-style design, using currently mature finite element analysis software for analysis and calculation, and through verification calculation by domestic universities, the overall weight is reduced by 30-50% compared to old domestically produced cranes. Advanced design methods and technical support from universities ensure the equipment's performance and safety. This type of equipment adopts European design, ergonomic design, comfortable operation; it has many advantages such as large lifting weight, small wheel pressure, stable operation, safe and reliable, high production efficiency, long service life, and small maintenance amount.

ME pipe-truss gantry crane: mainly used in the shipbuilding industry. This type of crane has a large span, large lifting height, and large lifting weight. It can withstand various harsh climates during use. Due to the high humidity and strong winds in coastal areas, the pipe-truss structure has significant advantages in this working environment.

MDG Truss Gantry Crane: This is a new type of gantry crane specially developed by our company for users' frequent disassembly and assembly, frequent relocation, initial installation without large mobile cranes, and variable usage environments. The main structure of the crane adopts steel or steel pipe truss structure, which has the advantages of beautiful and coordinated overall appearance, small windward area, strong wind resistance, light weight, low wheel pressure, simple disassembly and maintenance, low energy consumption, and low transportation costs.

Derrick crane: The crane arm adopts a pipe truss structure. The whole machine is designed to be simple and smooth, convenient for transportation and assembly, small footprint, large lifting capacity, light weight, excellent wind resistance, and strong scalability. It is suitable for loading and unloading large and overweight goods in ports, wharves or other fixed installation sites.

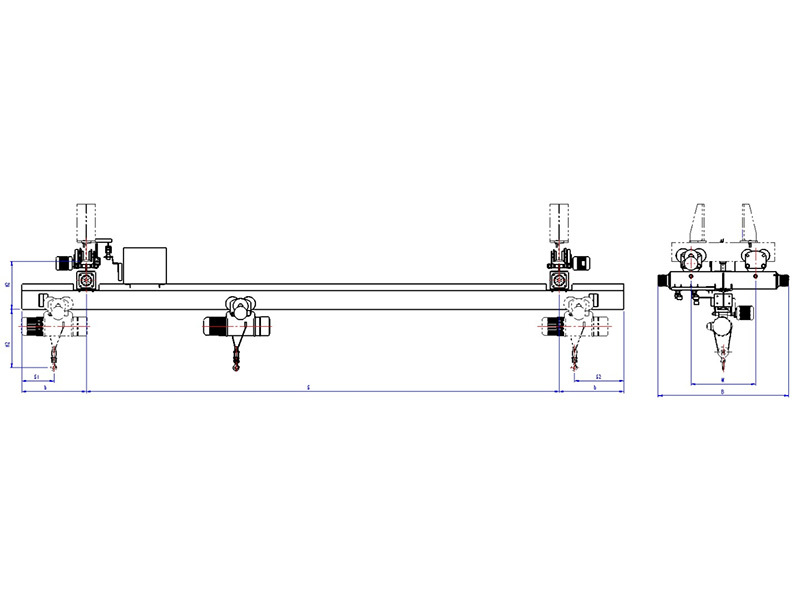

Generator stator lifting device

Generator stator lifting device: It features a simple structure, low cost, convenient installation and disassembly, short hoisting time, reusable multiple times, safe and reliable, and versatility.

Biomass intelligent grasping and feeding equipment

Biomass intelligent grabbing material equipment: lightweight and energy-efficient, successfully used in biomass power generation projects.

Hydraulic lifting molds are suitable for the construction of single-cylinder reinforced concrete chimneys or double-cylinder and multi-cylinder chimneys, as well as silo-type high-rise buildings. The hydraulic lifting mold construction method is superior to other construction methods such as vertical well frame turnover, slip forming, slip forming without well frames, and electric lifting molds, and is currently a more advanced construction method for chimneys.

Steel structure and factory EPC

Our company's product and service chain specially offers a comprehensive general contracting service for the design, manufacturing, installation, and lifting equipment of industrial plant steel structures, bringing convenience to owners while also creating broad cooperation opportunities.